BellHawk Systems provides barcode Work-in-Process tracking systems for manufacturers and other industrial organizations.

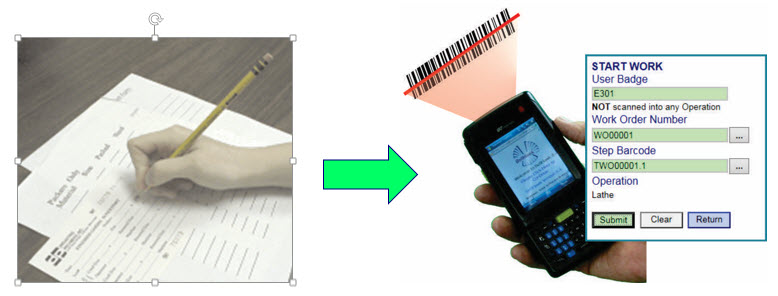

These low-cost and simple-to-use Work-in-Process tracking systems enable organizations to transition from using paper forms and manual keyboard data entry to using barcode scanning to track their Work-in-Process data in real-time.

These systems enable managers to see the status of jobs and customer orders in real-time as well as capturing the labor and elapsed time taken for each operation on each work order.

This information can be viewed in real-time anywhere there is an Internet connection on PCs, tablets, and smart phones. It can also be printed as reports or exported to Excel for subsequent analysis.

Work-in-Process tracking data can be captured on PCs equipped with barcode scanners, mobile computers with integral barcode scanners, or touch-screen tablets with Bluetooth connected barcode scanners.

BellHawk Systems provides:

SMTS - Simple Materials Tracking System can be used to track work-in-process as it moves from work station to work station with a single scan of a barcode.

SPTS - Simple Production Tracking Systema tracks the status of work orders for batches or individual products in real-time and the labor expended on each operation as well as the quantity produced.

RTOPS - an integrated Real-Time Operations Tracking System that expands on the capabilities of WIPS to track inventory, work-in-process, work orders, and labor. RTOPS also tracks materials produced and consumed by operations and uses BOMs to guide operators and prevent mistakes.

SMTS is designed for license-plate materials tracking and can be used to track the movement of work-in-process materials that have their own tracking barcode or are in a container, such as a tote, with a tracking barcode.

SPTS is designed for simple tracking and scheduling of batches or individual products as they travel through a sequence of operations, as well as capturing the labor time taken to perform the operations. It records when each operation starts and finishes.

RTOPS incorporates SPTS and SMTS and then adds more sophisticated work-in-process tracking capabilities such as tracking work-in-process inventory, handling split and merged batches, tracking machine times, as well as capturing materials traceability and activity-based-costing data.

For more information, please see Three Ways of Tracking Work-in-Progress

| Cost Savings | Technology |

|

Overview | Capabilities |

| Applications | Videos | Software Products | User Manuals | Data Sheets |

| Background | Partner Info | Frequently Asked Questions | Availability | White Papers |

| Technology |

|

Capabilities |

| Availability | Overview | White Papers |

| Background | Data Sheets | Videos |

| Cost Savings | Software Products | User Manuals |

| Partner Info | Frequently Asked Questions | Applications |

Copyright © 2025 Milramco LLC