Optional modules for the BellHawk software extends the capabilities of the BellHawk software platform to enable compliance with FDA, USDA, HACCP, and HIPPA regulations for tracking materials and ensuring compliance with quality assurance and materials traceability requirements.

This makes the BellHawk software ideal for tracking the manufacture, warehousing, distribution and processing of food, beverages, nutritional supplements, pharmaceuticals, medical supplies and equipment. It also makes the BellHawk software ideal for applications within laboratories, such as for tracking reagents and samples being tested.

The BellHawk software is CFR 21 Part 11 compliant thus making it suitable for FDA Good Manufacturing Practices validation.

The BellHawk software integrates manufacturing operations tracking, warehouse management, and materials traceability in one integrated software solution along with the ability to capture information such as the harvester, source location and grade of ingredients.

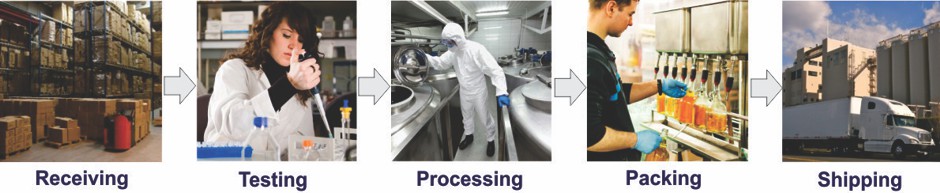

The BellHawk software makes extensive use of barcode technology to track materials from receiving, through put away, processing into intermediate products, packing into finished products and finally the picking, packing and shipping of finished products. It can also track and enforce quality assurance testing for raw, intermediate, and finished goods.

In the warehouse, the BellHawk software ensures that materials traceability is maintained from time of receipt to time of shipment, including generating GS1 compliant barcode labels and generating ASN(Advanced Shipment Notice) data for transmission by EDI software containing the materials traceability information required by large supermarket, restaurant, and pharmacy.

BellHawk captures materials traceability event data and the companion MilramX distributed decision support software can generate and send EPCIS files based on this data. This enables BellHawk to be integrated within food and pharmaceutical supply chain traceability initiatives.

The BellHawk software provides managers, supervisors, and customer service people with a real-time view of inventory, production operations, and customer order status. It can also track materials and their transformation in many different units of measure.

BellHawk software replaces the use of paper forms and manual keyboard with barcode scanning by material handlers and line operators. This not only saves the time of many people but also enables the system to prevent expensive mistakes by providing real-time point-of-action warnings before, and not after, mistakes are made. This includes preventing mistakes such as using ingredients that are contaminated or have not passed quality inspection.

BellHawk software captures all the data required for tracking and traceability compliance in a computer database so that it can quickly be accessed to provide the one-step-forward and one-step-backward recall data as required by the Food Safety Modernization Act of 2011, the FDA, USDA, HAACP, and similar requirements.

BellHawk software enables organizations to comply with requirements from large retail and restaurant chain organizations for electronic traceability with rapid recall capabilities. This includes performing mock-recalls at a push of a button.

With the addition of MilramX, the BellHawk software can be integrated with a wide range of accounting and ERP systems as well as with in-bound and outbound shipping and logistics systems. BellHawk can also automatically print container, pallet and shipping labels in customer specified formats as well as produce packing slips, bills of lading and ASN data for delivery by EDI software.

The BellHawk software quickly pays for itself in through savings in labor and in preventing mistakes. It also can minimize the scope and cost of recalls and even prevent bankruptcy.

Please click here to learn more about the Materials Tracking and Traceability Capabilities of the BellHawk Software.

| Cost Savings | Technology |

|

Overview | Capabilities |

| Applications | Videos | Software Products | User Manuals | Data Sheets |

| Background | Partner Info | Frequently Asked Questions | Availability | White Papers |

| Technology |

|

Capabilities |

| Availability | Overview | White Papers |

| Background | Data Sheets | Videos |

| Cost Savings | Software Products | User Manuals |

| Partner Info | Frequently Asked Questions | Applications |

Copyright © 2025 Milramco LLC