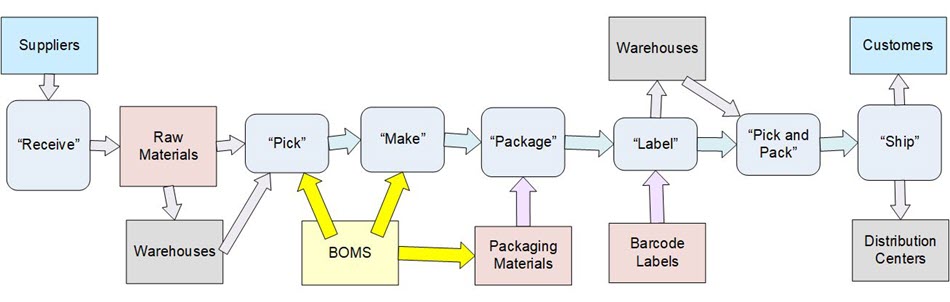

The BellHawk real-time data collection software tracks the receipt of raw materials, their transformation into intermediate and finished materials, as well as the picking, packing, and shipping of the finished products.

Because it is a work-in-process tracking system, BellHawk performs the tracking of the raw, intermediate, and finished materials using License-Plate-Number (LPN) container tracking methods.

These same methods can be used to track each part or container of parts as they move from work center to work center.

BellHawk tracks the transformation of materials based on work-order operations, which typically relate to the processing of a batch of materials, but which can also relate to the assembly, test, and repair of serial numbered equipment.

BellHawk can also track the transformation of materials by kitting, repacking, relabeling, and palletizing in an industrial warehouse.

BellHawk can track when a work starts and ends on each work-order operation. It can capture the labor and machine time required, as well as the materials consumed and produced, including scrap and materials returned to stock.

Comparison of Methods for Work-in-Process Tracking

It is recommended that clients start with the simplest method that meets their initial objectives. Then clients can always upgrade their BellHawk software to include the additional capabilities they may need in future.

| Cost Savings | Technology |

|

Overview | Capabilities |

| Applications | Videos | Software Products | User Manuals | Data Sheets |

| Background | Partner Info | Frequently Asked Questions | Availability | White Papers |

| Technology |

|

Capabilities |

| Availability | Overview | White Papers |

| Background | Data Sheets | Videos |

| Cost Savings | Software Products | User Manuals |

| Partner Info | Frequently Asked Questions | Applications |

Copyright © 2025 Milramco LLC